我的位置:首页 > 相关技术文献

TECHNICAL

相关技术文献Basics about Ozone

时间:2019-08-03 02:50:23 作者:admin  来源: 本站

来源: 本站

Production

The industrial production of ozone (O3) is always achieved by the reaction of oxygen atoms (O) with oxygen molecules (O2), and the former is generated simultaneously. Ozone production requires a gas ELECTRIC DISCHARGE COMPARTMENT (EDC), with two electrodes separated by a dielectric material. The dielectric material is used for isolation purposes, and to protect the current -bearing electrodes from short - circuiting.High-frequency, high voltage AC power applied on the electrodes produces ozone by means of "silent" or "dark" electrical discharge. The supply of electrical power produces an endothermic process, up to approx. 95% of which is released in the form of heat, which is dissipated by an cooling system, which may be air or water based.

An ozone generator refers a system that contains a REACTION MODULE(s) (ozone generating device) which contains one or numerous EDC cell(s), an electric supply unit, pipe lines for cooling water and gases, and a automatic control unit.

MWC value

The MAC value (Maximum Workplace Concentration) is defined as the maximum concentration of a substance, e.g. in the form of a gas, in the air in the workplace.At this concentration, no harmful effects to health are anticipated, even if an individual is subjected to this concentration for 8 hours on a daily basis (40 hours a week).

The MAC value for ozone is 0.1 ppm ≈ 0.2 mg/m³.

OTV value

The OTV value (Odor Threshold Value) is defined as the most minimal concentration of a gaseous substance that can be perceived by the olfactory sense.The OTV for ozone is 0.02 ppm . 0.04 mg/m3.

Efficiency of ozone production

The efficiency of ozone production is mostly measured by electric power consumption, which depends on many factors.Working temperature of an ozone reaction module

Any ozone generating device must be cooled, most likely by cooling water because of its effectiveness. Only very small ozone generators (less than a few grams per hour) may use air cooling means.The efficiency of a reaction module is greatly affected by working temperature, which is the temperature within the EDC, that can be roughly estimated by the average of temperatures of inlet and outlet of cooling water. The lower the working temperature, the higher the efficiency. The efficiency of an ozone generator can be doubled if the temperature drops from 30ºC to 15ºC. In most cases, a reaction module works at 5-32ºC. An ozone generator should not be used at any working temperature above 35ºC. Any efficiency measurement of an ozone generator should come with a specific working temperature. If the temperature is not mentioned, then 25ºC is assumed.

Feed gas

Oxygen or gases containing oxygen, such as compressed air or ambient air, is used as feed gas. The feed gas must be purified by filtered, free of oil and grease, and dry (a dew point of at least -45°C is necessary).Ozone generators can use either oxygen or air as the feed gas. Due to the low oxygen content in air and the difficulties to maintain the cleanness and dryness of air feed, it is highly recommended to use pure oxygen or oxygen enriched gas prepared from air by molecular sieves (90-95% oxygen) for ozone generation. If ozone is used in water treatment, higher ozone concentration in the gas form helps the dissolution and reactions of ozone in water. Using air will dramatically increase energy cost of ozone production.

Ozone concentration

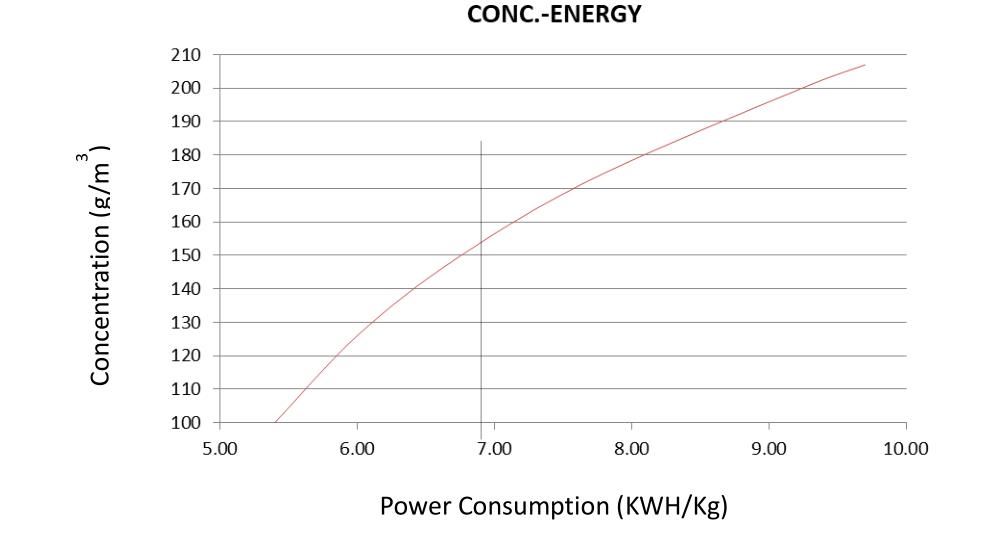

Ozone concentration can be measured by Iodine titration or UV light absorption. Since ozone decomposes along with the generation in the EDC, the higher the concentration, the lower the efficiency. At a high ozone concentration, less gas supply is needed for specific ozone capacity. Less gas supply also means less energy consumption. Higher ozone concentration also help the reaction of ozone. Hence, targeted ozone concentration should be considered for the total energy consumption including feed gas preparation and cooling, when an ozone application is designed.Any statement about ozone generation efficiency should come with a specified ozone concentration, 10% of ozone in pure oxygen (150g/m3) is usually aimed by ozone generators in the market.

Energy consumption at different ozone concentrations (25ºC, 92% oxygen)

Electric discharge compartment parameters

In general, lower voltage favors higher efficiency because the production of ozone is proportional to electric current. It is know that the narrower the EDC, the lower the voltage. It is an advantage for flat plate type of reaction module to reduces thickness of the EDP to ~ 0.2 mm over the glass tube type of reaction module which has ~0.5 mm thickness of EDC.The frequency inherent of flat plate type of reaction module is around 8000 Hz. The electric power efficiency of a ozone generator is significantly higher than the inherent frequencies of glass-tube technology.

In the EDC, ozone is produced and decomposed in the same time under the effect of dark electric discharge. To reach a certain concentration of ozone, the shorter pass-way of the EDC, the less chances for ozone to decompose. Flat plate ozone generator EDC pass way is about 200 mm, glass tube ozone generator can go as long as 2000mm when higher concentration is desired.

Electric power parameters

A reaction module at working conditions has a equivalent capacitance, which forms a LC oscillation with an inductance in the power unit at a specific oscillation frequency (OF), the reaction module works most effectively when the power unit supplies AC power at the same frequency of the OF. The power frequencies of the most ozone generators in the market work at a fixed frequency pre-set by the manufacturer, which should be close to the OF. However, the OF of a reaction module varies when the working conditions change. When a reaction module works at different production, a different gas presser, a different temperature and so on, a fixed power frequency is off-tuned and works at a lower efficiency. A much better power unit for an ozone generator should supply AC power at the exactly OF, and should be locked at the OF even the OF changes with the working conditions. Power unit with OF lock can also reduce energy consumption by heat releases from IGBT devices, and from the main transformer.Ozone applications

Disinfection

Ozone is a kind of broad-spectrum and efficient disinfectant and bactericide, having extremely strong killing effect for bacteria, mould, virus and other microorganisms. It has great superiority in terms of disinfection in hospitals and homes both for air and water, as well as treatment of some diseases. Ozone is widely used in disinfection of water in swimming pool and bottled water for drinking.One other promising application is using ozone to disinfect ship ballast water.

Water treatment

Ozone is also a very powerful oxidizing agent, it can oxidize almost all organic substances in water, and alternate the properties of such substances. This became very important for acute waste water treatment. When water is treated by conventional waste water treatment means, there are "left-over" substances which are less bio-degradable. If the resulted water needs to be treated further, the properties of those substances should have to be alternated. Ozone is the most "green chemical" to oxidize those substances into more bio-degradable forms and further to be removed by a following bio-process. Ozone can reduce the Chemical Oxygen Demand (COD) of water by itself as well. Ozone is widely used in drinking-water purification, treatment of medical and industrial wastewater, pretreatment for water reclamation.Gas and air treatment

Nitrogen oxides at lower oxidation state of nitrogen (NO, N3O2, NO2) are hard to be removed from gas that generated by combustion of fossil energy sources, especially coal, resulting air pollution. Treating such oxides by ozone yield much water soluble nitrogen oxides (mainly N2O5) which can be removed easily from the gas by water washing.Ozone is used in the removal of odor in gases and air.

Capacity calculations

Ozone capacity is calculated by:DO=c*Qn

where as:

DO--the capacity of ozone production, kg/h

c--the concentration of ozone, mg/L or g/m3

Qn--actual gas flow rate at normal conditions

When gas flow is measure by a float flow meter at conditions other than normal conditions, the readings have to be corrected according to the actual pressure and temperature; and according to the difference of gas densities if the meter is calibrated using a different gas or gas composition other than the actual gas or gas composition:

Qn= Qs

where as:

Qs--reading of a flow meter at actual conditions, m3/h

Ps--actual absolute pressure of the gas, Pa

Pn--absolute pressure at normal conditions, (1.013*105Pa)

Tn-- absolute temperature at actual conditions, K

Ts-- absolute temperature at which the meter is calibrated, K

Da--density of gas used for meter calibration , g/m3

Do-- density of the actual gas or gas composition, g/m3

For example, an air float flow meter (calibrated at 20ºC) is used to measure the flow of pure oxygen at a pressure of 1 bar (meter reading at 25ºC), the flow and capacity is calculated as:

Qn= Qs= =1.334*Qs

DO=c*Qn=1.334*c*Qs

when working conditions change, the calculation should be changed accordingly by the control board or by the PLC in ozone generator. Unfortunately some manufacturers give a fixed calculation formula in calculation settings which does not accommodate numerous working conditions.